We are manufacturer and supplier all type of fiberglass sheet printed sheet color sheet transparent sheet.

Fiberglass sheet manufacturing process.

98 of products ordered ship from stock and deliver same or next day.

The most common manufacturing process for fiberglass is the wet lay up or chopper gun spray process using an open mold.

8 fiberglass products come in a wide variety of shapes made using several processes.

We can customize the textures and standard colors of fiberglass flat sheet.

We hold all the aces in manufacturing supplying wholesaling and trading a wide array of fabricated products job works.

Mcmaster carr is the complete source for your plant with over 595 000 products.

Common items made of fiberglass include swimming pools and spas doors surfboards sporting equipment boat hulls and a wide array of exterior automobile parts.

Find here fiberglass sheet fibre glass manufacturers oem manufacturers india.

The shape of the part is determined by the shape of the mold and the mold surface is typically in contact with the exterior of the part.

Engineer helped them to solve many production problem and give more useful proposal at site.

Under this array we provide roofing sheds car parking shed industrial colour coated sheet shed petrol pump shed fabrication window roofing shed car parking shades fiber shed fibre glass product fibre glass product fiberglass sheet shade fiber sheets acp sheets.

Get contact details address of companies manufacturing and supplying fiberglass sheet fibre glass fibreglass sheet across india.

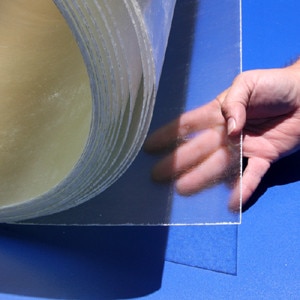

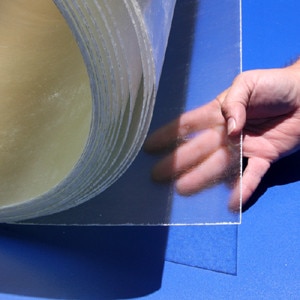

There is a layer of gel coat on the surface of fiberglass sheets.

For example fiberglass pipe insulation is wound onto rod like forms called mandrels directly from the forming units prior to curing.

The mold forms in lengths of 3 feet 91 cm or less are then cured in an oven.

We are wholesale supplier in fiberglass product.

1 easy and convenient manufacturing process.

Fiberglass american english or fibreglass commonwealth english is a common type of fiber reinforced plastic using glass fiber the fibers may be randomly arranged flattened into a sheet called a chopped strand mat or woven into a fabric the plastic matrix may be a thermoset polymer matrix most often based on thermosetting polymers such as epoxy polyester resin or vinylester or a.

Mold release is first applied to the mold to prevent the fiberglass part from adhering.

Once the fiberglass is woven together different resins may be added to give the product increased strength as well as allow it to be molded into various shapes.

2 good weather resistance.

Manufacturing with fiberglass.